Shot Blasting machines are enclosed chambers that have to bear extreme force produced by steel shots propelling at extremely high speeds. Since, shot blasting process produces both extreme force and friction the chamber and other components of the shot blasting machine is vulnerable to wear and tear at all times. Why unisyspro is the leading Shot Blasting Machine Manufacturer in India? We’ve mastered the technique of Shot Blasting over the past 15 years and manufacture high quality automatic shot blasting machines that are made of high quality steel combined with an extremely robust design. Automatic shot blasting machine manufacturing company in India that provides complete design, manufacturing, installation and service support to the customers across India and internationally.

Unisyspro is also a Leading supplier and Sandblasting machine Manufacturer in India, including Portable Sandblaster, Abrasive Blasting equipment and Shot Blasting Machines in Pune, Mumbai, Aurangabad, Ahmedabad, Rajkot, Faridabad, Jodhpur, Hyderabad, Kolkata, Coimbatore, Chennai, Bangalore, Gurgaon, Delhi NCR, Chandigarh, Amritsar, Punjab, and Maharashtra. Catering to the various industrial and engineering organisations across the country our shot blasting machine customers include Escorts Group, Talbros, HAL, IIT, Hindustan Platinum, Wanfeng Aluminium Wheel and many more. Among the Most affordable Shot Blasting Machine Manufacturer in India offering various sizes, models of abrasive blaster, sand blaster and abrasive blasting equipment. Industrial furnace manufacturer in India and a leading walk in refrigerator manufacturers

Sand blasting Machine, Sand Blast Hopper or Shot blasting machine or Shot Peening Machine can be your best investment when it comes to blast cleaning of various metal surfaces or floors as it saves times, labor and money compared to the traditional cleaning techniques or equipment.

Come explore with us how a Portable Sand blasting machine or a Portable Shot Blasting machine can help you cut costs and save time by preparing the surface for painting and powder coating. Sandblasting Hopper removes old paint, can be used for removing rust, deburring of forging parts, descaling of metal casting parts, paint stripping, paint removal and metal finishing.

All our sand blasting machine and shot blasting machine are manufactured in-house at our plants and sold by us directly so that we can offer you the best prices on the market. Our customers and our passion to create the long lasting sand blasting equipment have made us the leading Shot Blasting Machine Manufacturer in India.

What is Shot Blasting?

Shotblasting is a process which is used to clean, strengthen (peen) or polish metal components. Shot blasting Machine is used in almost every industry that involves metal components manufacturing or processing such as aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. Shot Blasting mainly deploys two technologies: wheelblasting and airblasting.

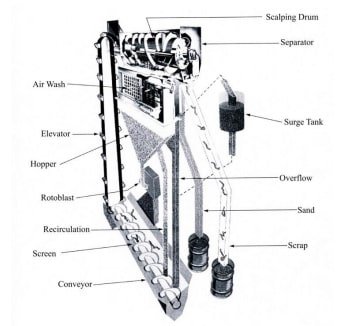

- Wheelblasting – is a Process that directly converts electric motor energy into kinetic abrasive energy by rotating a turbine wheel. A Shot Blasting machine uses wheel blasting technology for shot peening purpose onto the metal surfaces. The capacity of each wheel also known as bare wheel goes from approximately 60 kg per minute up to 1200kg/min based on the requirements. With these large amounts of accelerated abrasive, shot blasting machines are used where big parts or large areas of metal parts have to be cleaned, derusted, descaled, deburred, desanded or cleaned in some form to prepare the metal surface for further treatment or leave it as it is.

Shot blasting process is highly effective in removing burrs on cast iron parts and forged iron components using abrasive media. If you already have a shot blasting machine such as Tumble Blast then you can learn how to improve shot blasting process for better efficiency and results.

Here’s a very useful guide to understand the characteristics of shot blasting process.

Learn the Working Process of a Shot Blasting Machine

How to choose the Right Shot Blasting Machine Manufacturer?

Sometimes it becomes difficult for the companies to choose the right shot blasting machine for their blasting purpose. In order to pick the right model of a Shot blasting machine you need to consider the method of transportation of the components to be blasted that will define the type of the machine you require such as: Tumb Type Shot Blasting Machine, Cabinet Type shot blasting machine, Cabinet Type Sandblasting Machine, Stone Shot Blasting Machine, Spinner Hanger Type Shot Blasting Machine, Table Type Shot Blasting Machine, Blast Room and many other models.

Applications of Shot Blasting

Shot Blasting Applications

Shot Blasting process is in use for over hundred years as it helps in surface preparation and sometimes to change the properties of a metal surface. The major industries where Shotblasting is an integral part of the manufacturing process includes:

- Automotive Industry

- Profile and belt descaling

- Construction Industry

- Foundry and Forge Industry

- Aerospace Industry

- Energy

- Steel Fabrication

- Aluminium Industry

- Rail Shipyard

- Medical Equipment Manufacturing

- General Manufacturing

- Military & Defense Manufacturing

- Strip and Tube De- scaling, etc.

Two Unique Applications of Shot Blasting in Concrete & Steel Industries:

Shot Blasting is used to produce a surface profile on the substrate, and it’s benefits are listed below.

- To achieve better adhesion properties for the application of epoxy coatings, paints, waterproofing primers, etc.

- To Create or re-instate slip resistant properties by achieving a rough surface.

Shot Blasting is also used to remove the existing material from the substrate which are listed below.

- Remove contaminants from the surface of the steel

- Remove paints, coatings, rust and sealants from the steel

- Remove laitance from the surface of concrete

Since, the coatings and overlayment products have seen major improvements in the recent years, shot blasting process has been widely utilized across various industries for surface preparation including steel fabrication and construction industries.

Shot Blasting Produces a Surface Profile and Removes Existing Material.

- Commercial

- Food processing

- Retail

- Institutional

- Parking garages / waterproofing

- Manufacturing

Steel industries have two primary applications of shot blasting such as to produce a profile and remove existing material from the surface of the material. The major use for shotblasting machine on steel surfaces are in ship building industry, steel fabrication industry, bridges construction, storage tanks, food plants components and automotive components. Shotblasting can be carried out on both vertical and horizontal surfaces.

Shot Blasting Technique Introduction

The final stage in the manufacturing of metal, iron, steel, forging to casting products involve the surface treatment and finishing of the products surface to remove the residues, contaminants and other deposits such as in case of a casting product where the moulding and core mix have to be removed to obtain the required surface quality and condition.

Among surface treatment methods, mechanical methods seem prevalent, particularly the abrasive (or shot blasting) methods because it’s highly efficient and economical at the same time. Advantages such as low energy consumption, high quality of treated surfaces, good potentials for process automation, the use of shot blasting machines made of more durable materials, work safety and environment-friendly features such as dust free blasting.

In shot blasting processes a stream of abrasive medium with the required kinetic energy is generated and propelled onto the surface to be treated. The stream of the abrasive material, being a mixture of metal shots, is a dynamically variable system, involving a concentrated and dispersed zone, as revealed by numerous studies. The actual proportion of particular zones in the structure of the shot stream strongly impacts on the shot blasting efficiency. The greater the concentrated zone, the more effective the process. Other determinants of shot treatment efficiency include:

- satisfying the criteria underlying the design of blast mechanisms

- properties of the cleaning agent which has to meet the specific process requirements

- the optimal shape of the shot stream in terms of its geometric, kinetic and dynamic parameters

- direction of the jet hitting the surface of the treated field. These factors determine the surface quality of shot-treated castings.

In terms of operational requirements, the sleeve position is of key importance. It is defined by the slot’s inclination angle with respect to the horizontal plane. The value of this angle determines the dynamic behaviour of abrasive agent ejected under the action of the centrifugal force. Test results reveal that the best dynamic effects are achieved at the angle of 20 degrees. The key mechanism at the final stage in the controlled circulation line of abrasive agent is the blast rotor with blades.

What is Sand Blasting or AirBlasting?

Airblasting or Sand Blasting – is a process of cleaning metal surfaces using compressed air as the fuel and Blast Abrasive materials that are propelled at high speeds using Compressed air. Airblast machines come in the form of a Sandblasting cabinet, the blast media is accelerated by compressed air and projected by nozzles onto the metal surface. There’s another vapor blasting process known as wet blasting which is completely dust free and a wet blasting machine is used to carry out the process.

The blasting task determines the choice of the abrasive media, in most cases any type of dry or free running abrasive media can be used. For special purpose blasting dry blast media and water can be mixed which is called wet blasting.

Actual Working of a Sand Blasting Cabinet Machine from Maan Global Industries

Above is a working demo of a Sand Blast Cabinet attached with a Dust Collector for Pollution free blasting. It works with compressed air for blasting media on the surface of the component and also has a turntable for 360 degrees component blasting.

Among the most affordable Sand Blasting Machine Manufacturer in Faridabad, Delhi NCR, Pune, Punjab, Jodhpur, Chennai, Mumbai, Ahmedabad, Coimbatore and Sandblasting Machine in India for over a decade.

We also provide Blasting Abrasives like Aluminum Oxide, Cut Wire Shots, Steel Grits and Steel Shots etc. Also offering Shot Blasting Machine Spares, Sand Blasting Hood and many more. All our products are corrosion resistant with accurate dimension, fine finish, high strength, not required much maintenance and long life. We also provide Sand Blasting Services which is known for reliability, long serviceability and cost-effectiveness. The above offered products are in a variety of specifications to cope up with the requirements of patrons.

We have a large customer base whom we provide our cheap shot blasting machine in Raipur, Bhilai, Varanasi, Tiruppur, Rajahmundry, Bokaro Steel City, Raigarh, Nashik, Vijayawada, Gurgaon, Karnal, Panipat, Rohtak, Ambala, Hisar, Margao, Katni, Baddi, Faridabad, Nagpur, Visakhapatnam, Durgapur, Kharagpur, Haldia, Indore, Hosur, Mumbai, Pune,Jamnagar, Bharuch, Thane, Kolhapur, Rourkela, Pithampur, Aurangabad, Kolkata, Ghaziabad, Noida, Bikaner, Jodhpur, Ajmer, Jaipur, Udaipur, Kota, Kannur, Bhilwara, Alwar, Bareilly, Moradabad, Belagavi, Sangli, Saharanpur, Agra, Kanpur, Meerut, Aligarh, Allahabad, Salem, Mathura, Jhansi, Punjab, Chandigarh, Jalandhar, Amritsar, Ludhiana, Bathinda, Pathankot, Patiala, Hoshiarpur, Shimla, Kochi, Bangalore, Belgaum, Tamil Nadu, Uttrakhand, Dehradun, Haridwar, Roorkee, Rudrapur, Rishikesh, Assam, Guwahati, Agartala, Shillong, Bihar, Patna, Gaya, Bhagalpur, Ahmedabad, Rajkot, Vadodara, Jammu, Bhopal, Hyderabad, Muzaffarpur, Jharkhand, Jamshedpur, Dhanbad, Ranchi, and many more cities. Exporting to countries such as Nepal, Bangladesh, Malaysia, Sri Lanka, South Africa and Kenya.

Manufacturer of Various Types of Shot Blasting Machines including:

- Sandblasting Machine & Shot Blasting Machine Service

- Sand Blasting Machine Manufacturer

- Shot Blasting Machine Manufacturer

- Soda Blasting Machine

- Nozzle Manufacturers

- Blast Room / Chamber

- Paint Booth Spray Systems Manufacturer

- Soda Blaster

- Blast pot

- Sandblasting Cabinet

- Bead Blasting

- Grit Blasting

- Dustless Blasting

- Pressure washer

- Tungsten Carbide Nozzle

- Cleaning Equipment

- Roller Conveyor Shot Blasting Machines for Pipes and Garters.

- Paint Spray Booth Manufacturers

- Core Sand Mixer

- Concrete Mixer Machine

- Concrete Batching Plant Manufacturers

We are also the suppliers of all types of New & Old Shot Blasting Machines and all kinds of Spares for any type of Shot & Sand Blasting Machine. In an age where superiority is determined by balancing qualities of design, technology and prompt services, UNISYSPRO leads the way combining its resources and is also a leading industrial oven manufacturer in India. Efficiency and superior quality maintained has been the cornerstone in providing competitive services, machinery and support to the blasting and painting industry. We take pride in every aspect of our manufacturing process to provide the professional touch in our business. This allows us to be responsive to customer demands in a dynamic business environment today. We actively work with our customers for the optimal solution. We believe in manufacturing the highest quality sand blasting machines, at competitive prices, that will exceed our customer’s expectations. unisyspro stays committed to the core values of excellence and customer satisfaction and endeavors to add to the product line-up with better precision and productivity in the years ahead.

Our customers include Escorts Group, JBM Group, Lakhani Industries, Honda Motors and many other leading small and mid sized companies that require highly reliable and affordable sand blasting machine as well shot blasting machine. We also provide abrasives of various kinds that are used for Sandblasting and Shot blasting purposes at whole sale prices. With a world class team of technicians, experienced managers and product designers, we have grown into a full-fledged corporation catering to the needs of the leading companies on the market.

Having a large pool of talented machine designers and technicians we are able to come up with products for the blasting industry that are extremely affordable and highly reliable. With an experience of over 2 decades in the blasting industry we are among the leading manufacturers of sandblasting machine and shot blasting machine in India. We have two plants, a full-fledged Software Technology Centre for product innovation and we organise student visits at our plants on a regular basis.

Abrasive Blasting Equipment and Product Range:

We are supplying a complete range of surface preparation and coating equipments at highly affordable prices. We source our products from renowned vendors in the industry. Our range of products as given below:

- Portable Sandblasting Machine

- Tumblast Shot Blasting Machine

- Blasting Safety Equipment

- Air Compressors 3HP to 50HP

- Blast Nozzles

- Astro Abrasive Blasting Helmet

- Extreme Nxt

- Airless Sprayers

- Airless Paint Gun and Accessories (Dry, Wet Film & Materials Thickness Gauges)

- Blast Light

- Blasting Ventilation Systems

- Internal Pipe Cleaning & Coating Equipment

- Nozzles and Holders

- Elco Meter

- Entire Range of Elco Meter

- Paint Finish Equipment

- Entire Range of Graco’s Equipment and Accessories

- Hose Couplings & Clamps

- Spray Guns

- Entire Range of Spray Guns Available.

Stockist, supplier & Exporter of Sand Blasting Abrasive material such as:

- Zinc Shots

- Aluminium Shots

- Cut Wire Shots

- Standard Steel Shots

- Aluminium Oxide

- Glass Beads

- Steel Shots

- Copper Slag

- Walnut Shells

- Stainless Steel Shot

What is the Price of a Portable Shot Blasting Machine?

If you are looking for a cheap shot blasting machine with 80kg shot blasting capacity in one cycle for cast iron parts, foundry, forged components or engine part cleaning, Tumblast Shot Blasting Machine is suitable and affordable for Rs. 2,50,000 only.

For Auto body cleaning and blasting Sand Blasting machine at Rs. 24,000 only, manufacturer of Paint Spray booth systems in India, Shot Peening machines, Shot Blasting Machine Manufacturers in India, media blasting and Abrasive blast equipment at best prices in India.

What is Shot Blasting Process?

Shot blasting process is used to prepare metal or steel surfaces by removing dirt or other contaminants and also prevent metal products from cracking through shot peening to achieve higher tensile strength. Steel Shots are used to remove impurities, rust, scattered pieces of rubbish or remains of core sand during metal castings that may affect the finish of the surface. Shot Blasting is an environment friendly and a cost effective surface finishing method. It can be used for cleaning, polishing metal and other surfaces such as of steel by projecting a stream of shots propelling at high velocity.

What is the difference between shot blasting and shot peening?

Shot blasting is a process of preparing metal surfaces, before metal undergoes further processing, it is required to prepare the surface in order to ensure that the deposits such as dirt and other impurities is off the surface. Shot Blasting helps in ensuring that the surface is extremely clean in order to enhance paint and coatings adhesion or achieving the desired surface finish.

Shot Peening helps to increase the strength by applying pressure to the surface of the metal. It causes the metal to expand, releasing tensile strength and creating compressive stress. Various industries make use of shot peening process to increase the strength of the metal surface.A shot blasting machine is extremely useful in achieving high tensile strength using Shot Peening process.

What Abrasive materials are used for Shot Blasting?

Different types of abrasive media are used in Shot Blasting for cleaning, polishing and peening of the metal surface. The choice of abrasive material for shot blasting depends on the surface to be prepared. Most common material for Shot Blasting are Steel Shots that are available in various sizes and strength. Steel shots are used for surface cleaning and achieving a surface profile before the coating and painting process. Another abrasive material such as steel grits are used to achieve surface roughness on tough surfaces, or to remove flashes in forging or de-scaling and deburring in metal castings.

Other Abrasive media used in Shot Blasting are Steel grits, cut wire shots, zinc shots etc., all have different purpose from smoothening rough metal surfaces to preparing and polishing aluminium surfaces. Abrasive materials vary in cost and the larger quantity you buy, the less would be the cost.

What are the advantages of Shot blasting machine?

- It is an environmentally friendly machine that is useful in removing corrosion without the help of harmful chemicals and to prepare metal surface before further treatment.

- Shot blasting machine is extremely cost effective as compared to other methods of surface preparation.

- A Shot blasting Machine treats higher volume of metal components in much less time compared to other manual methods.

How to choose a reliable Shot Blasting Machine Manufacturer in India?

Shot Blasting Machines are both cheap and expensive. Cost of a shot blasting machine varies based on the design, quality of materials used and the type of machine. A portable shot machine would cost only Rs. 2.5 lakhs while a Hanger Type Shot Blasting machine could cost anywhere between 7.5 lakhs to 12.5 lakhs.

When you are looking for shot blasting machine manufacturers in India Industries is the leading manufacturer of Sand Blasting Machine and Shot Blasting Machines. It has nation wide presence and customers across various industries from Auto ancillaries to OEMs to Aviation companies to Construction companies.

Contact the best Manufacturer of Shot Blasting Machine in India, Mumbai, Pune, Faridabad, Jodhpur, Maharashtra, Gujarat, Delhi, Hyderabad, Bangalore, Jamshedpur, Punjab.

Contact the best Manufacturer of Shot Blasting Machine in India, Mumbai, Pune, Faridabad, Jodhpur, Maharashtra, Gujarat, Delhi, Hyderabad, Bangalore, Jamshedpur, Punjab.

For Sand Blasting Machine Manufacturer in India. All types of Sand Blasting Machines at best prices including Sand Blasting Cabinet, Portable Sand Blaster and Abrasive Blasting Machines.

Call: Mob. 8527678886 or fill out the contact Us form or, Email: info@unisyspro.in